Ska's Sustainability Initiatives

We are always looking for ways to improve our sustainability efforts.

This includes using recycled jeans in the walls as insulation, reusing bowling alley wood as tables and installing solar panels, and more.

We are always looking for ways to improve our sustainability efforts.

This includes using recycled jeans in the walls as insulation, reusing bowling alley wood as tables and installing solar panels, and more.

![SKA SOLAR[96]](https://skabrewing.com/wp-content/uploads/2023/05/SKA-SOLAR96.jpg)

![SKA SOLAR[96]](https://skabrewing.com/wp-content/uploads/2023/05/SKA-SOLAR96.jpg)

We have been long committed to reducing waste and developing brewery and distribution systems that minimize our carbon footprint— from recycled jeans in the walls as insulation and reused bowling alley wood as tables, to solar panels, solar lighting, wind energy credits, and recycling of all cardboard, paper, plastic, glass and metal waste.

We were one of the first craft breweries in the country to package our beer in infinitely recyclable aluminum cans, and we now have many packaging systems in place to further conserve resources, including Ionized air rinse instead of water rinsing and an efficient, on-demand, de-aerated water system. These are just a few of our sustainability programs that we are constantly improving upon.

In 2023, we continued these efforts alongside the implementation of two sizable and unprecedented sustainability initiatives. We installed a machine that will allow for the transition of all can collars from plastic to paperboard, making us one of the first breweries ever to utilize this equipment in the effort to move away from plastic packaging materials.

Secondly, Durango’s Table To Farm Compost will now be the recipient of all of our spent grain. This transition from cattle feed and landfill to compost will reduce methane emissions and align with our commitment to local partnerships.

In 2023, we installed the CanCollar® Corsair™ machine provided by WestRock. We are the first craft brewery in North America to implement this automation solution, which will enable our transition from plastic rings to a fiber-based solution for our multipack product wraps.

We have never been keen on plastic packaging, but we recently identified an alternative that supports our sustainability goals.

WestRock, a global paper and packaging leader dedicated to sustainability whose portfolio includes solutions for craft and artisanal beverage producers. The company’s CanCollar® Corsair™ machine automatically applies various CanCollar® paperboard-based multipack formats to 24-pack trays of product, which gives us the ability to package all of our canned brand offerings — including four-packs and six-packs — using a solution that reduces plastics consumption by up to 95 percent when compared to alternative plastic multipack options.

The CanCollar, which promotes circularity, will immediately reduce the amount of plastic we contribute to the environment by approximately four tons per year. This contributes to a reduction in overall waste and the carbon footprint associated with the shipping and storage of our products.

Our ultimate goal is to become zero waste and divert everything from the landfill.

We have moved toward composting our spent grain by giving it to local recycling company Table to Farm Compost. Spent grain is the waste created during the brewing process. To complete this process, a spent grain silo collection system has been added to our brewery. You will also see us driving around a 4,000 gallon tanker truck to transport the grain to Table to Farm.

We have projected to go through at least two million pounds of spent grain per year.

Previously, we donated the spent grains to local cattle farmers who would use the grains to feed their cattle, however, at times it would end up in the landfill.

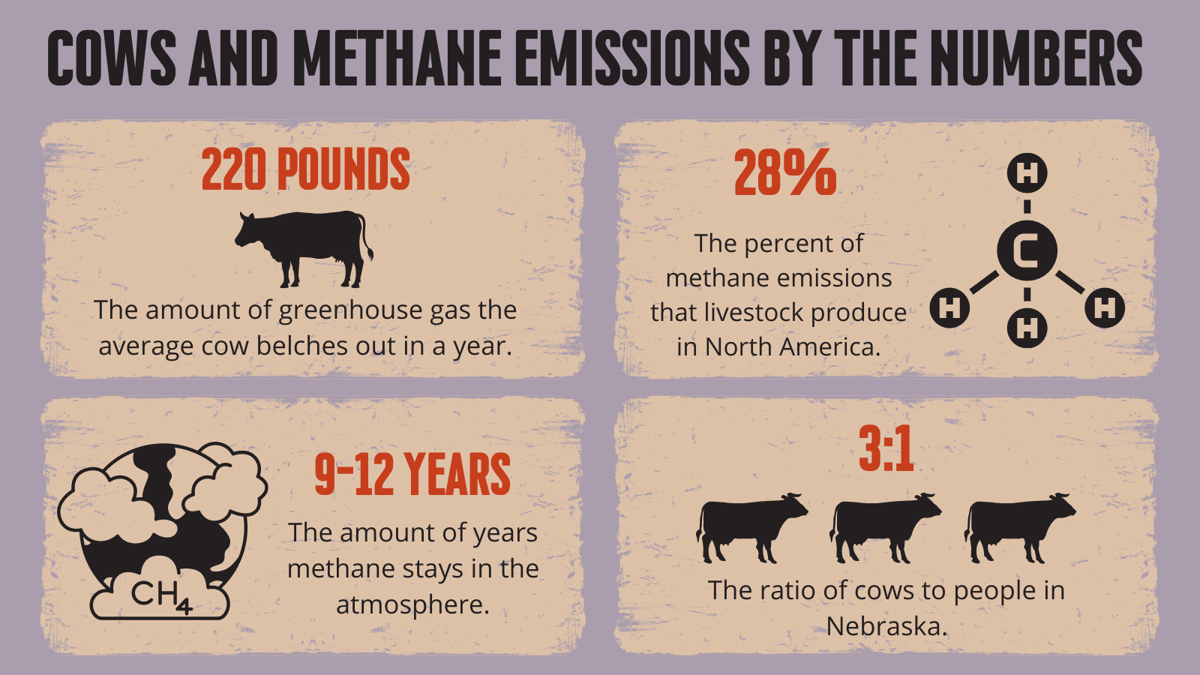

Cattle do not do a good job of digesting the lignin and cellulose in the spent grain, which creates methane through cattle flatulence.

According to the Environmental Protection Agency, methane accounts for 20% of global emissions and is more than 25 times as potent as carbon dioxide at trapping heat in the atmosphere.

Table to Farm will receive the grain and then sell it to people who want to use it as fertilizer or for other composting purposes.